Infrastructure

Patelmech prequasine pvt. Ltd. factory area is spread over 20000 sq. ft., comprising of 03 Units for different processes.

- Factory 2 is 8000 sq. ft., constructed in 20000 sq ft.

- Factory 1 is 15000 sq. ft, constructed in 25000 sq ft.

The entire department is well equipped with the hi-tech technology, machineries and updated time to time. The organization consists of Quality Control, Production Unit, Administration & Accounts Department, Electro Plating /Heat Treatment units, Drawing Office, Tool Room & Packaging / Dispatch department.

The Research and Development Division at Patelmech prequasine pvt. Ltd. consists of a highly qualified, experienced and Professional team which aims for constant up gradation and Facilities without making any compromises on product design, raw materials, manufacturing process, finish and quality.

All department managed by Qualified & Well-Trained Staff, so as to ensure the best Quality material.

List of Quality Control Equipment and Machinery

- Hardness Testing Machine.

- Calibrated Gauges & Callipers.

- Plating Thickness Measurement.

- Salt Spray Test Machine.

- Electro Micro testing facility.

- Torque Range testing facility.

- Electro Platting Micro Checking Machine -Fischer Germany

- Measuring instrument

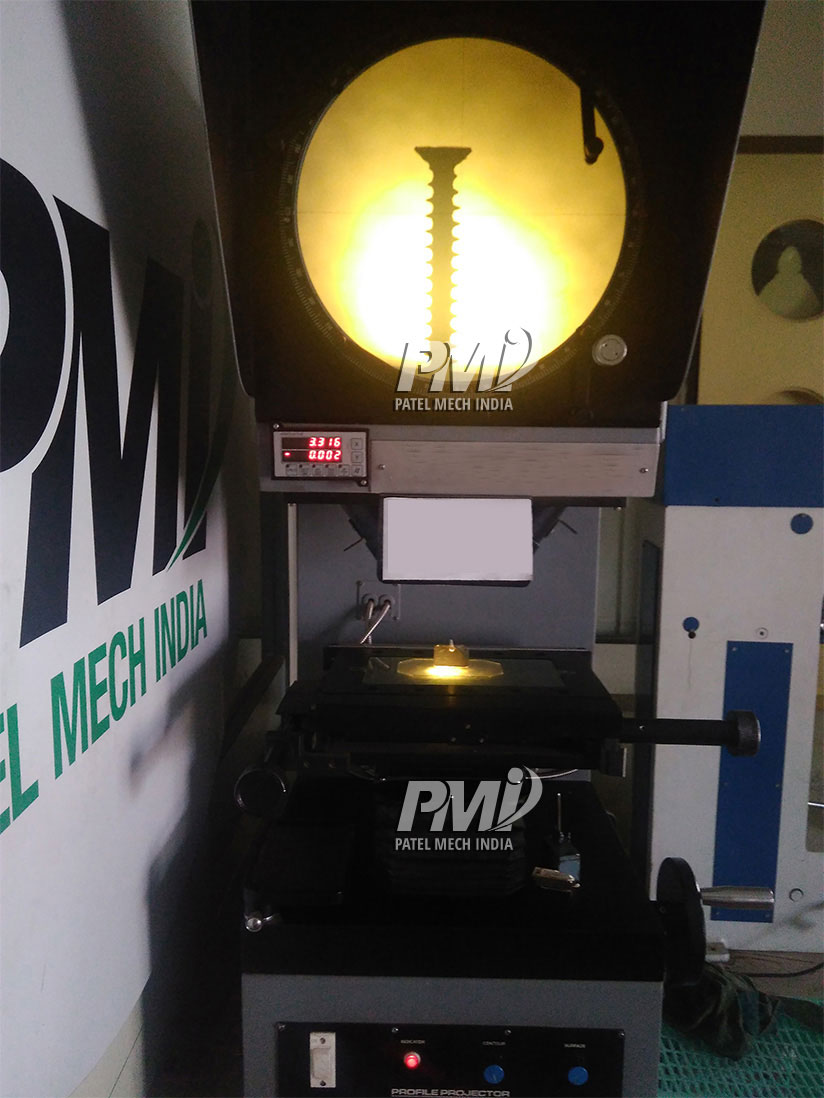

- Profile projector

- Specifications Confirming to International Standards

Production Unit

- Header

- Slotting Machines

- Chamfer Machines

- Threading Machines

- Turning Machines

- Grinding Machines

- Drill Machines

- Dryers

- Drum Machines

- Universal Slotting Machines

Electro Plating Department

- Pre-Clean (Ultrasonic)

- Metal Cleaner Clean

- Water Swill

- Plating Thick Barrels

- Dryer + Waxing + Oven

Production

-

Raw Material Area

-

Wire Draw Machine

-

Wire Draw Machine

-

Wire Washing Area

-

Sparadise Annealing Furnace

-

Sparadise Annealing Furnace

-

Header Department

-

Header Department

-

Threading Department

-

Brass Nut Threading Machine

-

Brass Turning Components Department

-

Hole Drilling

-

Material Feeder in Threading

-

Radius Department

-

Slotting Machines

-

Automatic Heat Treatment

-

Dryer-Machine

-

Auto Plating Plant

-

Auto Plating Plant

-

Brass Natural Wash & Plating Area

-

Dies & Tools in Tooling Area

-

Tooling Area

Quality Control

-

Electro Platting Micro checking Machine

-

Hardness Testing Machine

-

Optical Sorting Machine

-

Profile Projector

-

Salt Spray Test Machine

-

Vision Inspection System

-

Visual Checking

Packaging & Storage

-

Assembling & Packing of Material

-

Material Storage Area

-

Ready to Dispatch Area

-

Storage Department

Office Area

-

Office Reception Desk at Factory 1

-

Reception Area at Factory 2

-

Reception Area at Factory 2

-

Reception Area at Factory 2