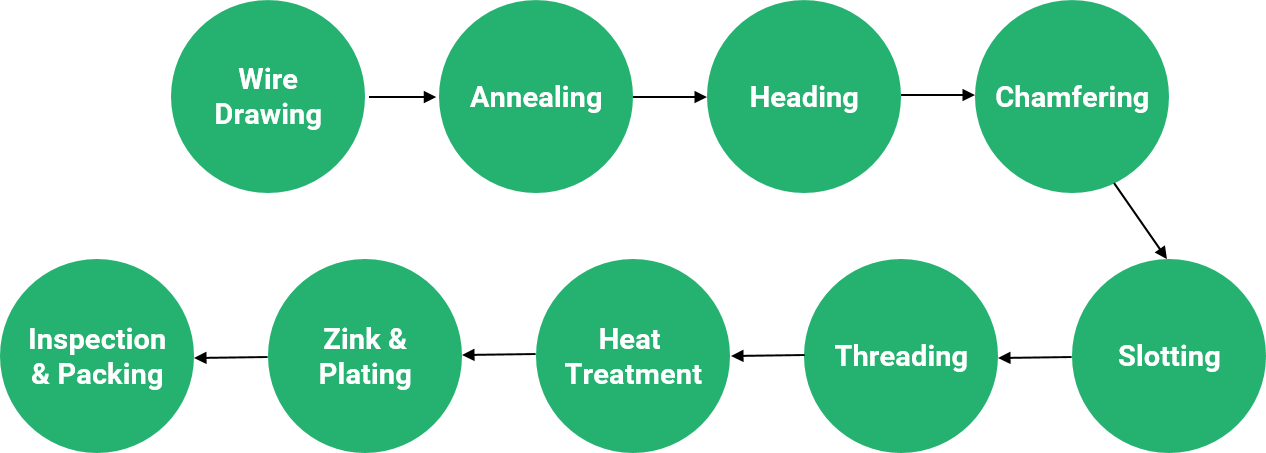

PATELMECH PREQUASINE PVT. LTD. has years of expertise in manufacturing brass and steel fasteners and exporting it to various industries across the globe. Our Fasteners are manufactured with fully integrated facilities like Wire Selection/ Forging /Forming/High Speed thread rolling/ High Speed slotting/ High speed tapping/ Heat treatment, In House Plating Facility, In-House inspection facility with latest inspection equipments backed up by computerized counting. All these ensure Quality Product.

We have well established fasteners manufacturing process to meet the specific requirements of customer across various industry. All manufacturing processes are carried out in-house with latest technology and modern machinery with best in class Quality Management System.

- Wire Drawing:

Wire drawing is a metalworking process used to reduce the cross-section of a wire by pulling the wire through a single, or series of, drawing die. It is carried out to get the required wire size for cold forging the parts depending upon the size of fasteners to be manufactured. - Annealing:

Annealing is an important step in the cold forming process for fasteners as it ensures that the microstructure of the brass and steel is soft and has maximum formability. - Cold Heading:

Cold heading or forging is the process of forming ferrous and non-ferrous materials into specific configurations, without the use of applied heat to assist the formation process. - Chamfering:

Chamfering is a process for finishing machined parts as per customer specification and requirements. It is used to make a bevel, groove or furrow. - Slotting:

Slotting is the process of forming or cutting the slot on the head of a fastener during wither the primary or secondary operation. - Threading:

Threading is a process to create threads on the inside or outside of the fastener using thread rolling dies. - Heat Treatment:

Heat Treatment is a process to increase the overall durability of the fasteners. It is done within two operation includes Hardening and Tempering. Hardening is performed to heat fasteners at high temperature and Tempering is performed to reduce some of the excess hardness/brittleness of the fastener. - Zinc & Plating:

Zinc & Plating is a process to prevent the fasteners damage or malfunction from critical environment condition, rust or corrosion, etc. with the Coating. - Inspection & Packaging:

This process involves the product testing by quality assurance department to ensure international standards and secure nationwide and international delivery services for fasteners across the world.